Choosing the Right Dual-Axis Solar Tracker for Your Project

Dual-axis solar trackers–especially elevated ones–represent the current state of the art in solar technology. They enable significantly increased solar energy collection on a smaller area, and if elevated, the ground beneath them remains available for other uses, serving a variety of profit-generating or community functions.

While elevated dual-axis solar trackers have unrivalled benefits, they also require careful engineering and an experienced installer.

What to look out for when choosing a dual-axis solar tracker system

A well-designed and well-built dual-axis solar tracking system using the latest technology will perform reliably for decades with little maintenance.

However, not all dual-axis solar trackers are created equal. They are more complex systems than traditional fixed solar panels or even single-axis trackers, therefore precision design, advanced technology, and high-quality materials all play a more important role in their performance, durability and safety.

So, what should you look out for when deciding on a dual-axis solar tracker solution? How do you choose the right manufacturer from an ever-expanding range?

Ask about the materials used which are key for durability

Some dual-axis solar trackers are built using cheaper, and less reliable, aluminum components to reduce costs. This is partly because some manufacturers have been trying to keep prices down to compete with single-axis trackers. With the more complex technology of dual-axis tracking, however, such price competition is not a realistic goal. Short-term savings can cause major headaches in the long run. Think of the environmental conditions a solar tracker must withstand for (ideally) 30 plus years: rain, snow, heavy winds, scorching sun, dust, and dirt. A structure made entirely of structural steel can cope with these challenges for much longer than their cheaper aluminum or low-grade steel counterparts. Choose an all-steel dual-axis solar tracker whenever possible. This is particularly important for elevated dual-axis systems because safe operation of arrays at 20 feet above ground requires a high degree of stability and material strength.

Tolerance is another key aspect of solar tracking design that leaves no room for compromise. The build quality of solar trackers is determined by the way different parts of the drive core, such as the worm drive gears, the spur gears, as well as the bolts and plates are connected at each step of the way, down to the foundation. If you have sloppy holes or connections, if these parts are not as tight as they should be, then over a few years, vibration can destroy the screws or gears and the tracker will lose its ability to track accurately and perform safely. The screws that hold the plates together will also produce friction. If any of these pieces loosen after years of exposure to wind and the elements, they will eventually start to fail. If the slew drives and gears are not tight enough, if they are not made of strong enough materials, they may lose their accuracy and may also fail structurally. Perhaps not within 10 years, but sooner or later... And when that happens, repairs are a serious headache and carry a heavy price tag.

Tip: Stracker Solar's elevated dual-axis solar trackers are made entirely of solid structural steel, which is by far the strongest material in terms of bending strength, as well as sheer strength.

Ask about the drive core which is the heart of solar trackers

The most complex, vulnerable, and expensive components of dual-axis solar trackers are in the drive core mechanism. Some manufacturers use hydraulic motors and linear actuators, both of which can be the source of a variety of problems. A typical example is hydraulic tank leakage, which makes the tracker stop moving until replaced. These drive systems are often built of galvanized steel and aluminum, have plastic components as well, and they don't meet the structural code requirements of many states. Slew drives are a more durable solution, yet fewer manufacturers use them because they are more expensive, require a higher level of precision to install and the material strengths have only recently become reliable enough for decades of strong performance.

Tip: Stracker Solar uses two electrically driven slew drives per array instead of less reliable hydraulic motors or linear actuators.

Ask about the warranty which is your assurance

Not all quality concerns can be tested, certainly not by a layman. High quality materials, fine tuning of gears and precision in assembly make a huge difference to the performance and durability of dual-axis solar trackers. But you cannot inspect all the screws and bolts before making a purchase decision. How can you have confidence that your solar panel system will work well in the long run?

That’s where structural warranty comes into the picture.

When you calculate your return on investment, you need to consider your warranty very carefully. The return on a system with a 10-year warranty is quite different from the return on a system with a 35-year warranty. After your 10-year warranty expires, you will be responsible for the cost of troubleshooting and repairing any structural defects, which can significantly reduce the return over a longer period. Especially when you factor in that manufacturers who only offer a 10-year warranty are likely doing so because they know that their system failure rate beyond 10 years is too high.

Tip: Stracker Solar uniquely offers a 30-year structural warranty on its elevated dual-axis solar tracking systems.

Find out about maintenance

In addition to a short warranty period, maintenance costs can be another significant hidden expense of solar PV systems that some people may not consider at the time of purchase. On the other hand, some more careful others may be concerned about the perceived high maintenance costs of solar trackers. The fact is that not all systems are created equal in this respect. In addition to build quality, the highest possible level of automation and outstanding performance are also crucial factors. For a well-designed dual-axis solar tracking system, no maintenance is required beyond the simple annual greasing of moving parts and checking paint for potential touch-up. Cleaning is generally needed for solar trackers that sit low to the ground. With such models, especially in case of larger installations, an extra challenge customers face is how to keep the grass short under the solar trackers so that it doesn’t shade the solar panels. Snow cover is generally not a problem since dual-axis solar trackers move and naturally dump snow in their most vertical position twice a day.

Tip: Stracker Solar's elevated solar trackers don’t need cleaning. The panels don’t collect ground-level dirt and dust due to the elevated position and constant movement of the arrays. Long grass or cutting the grass under the units are not issues either.

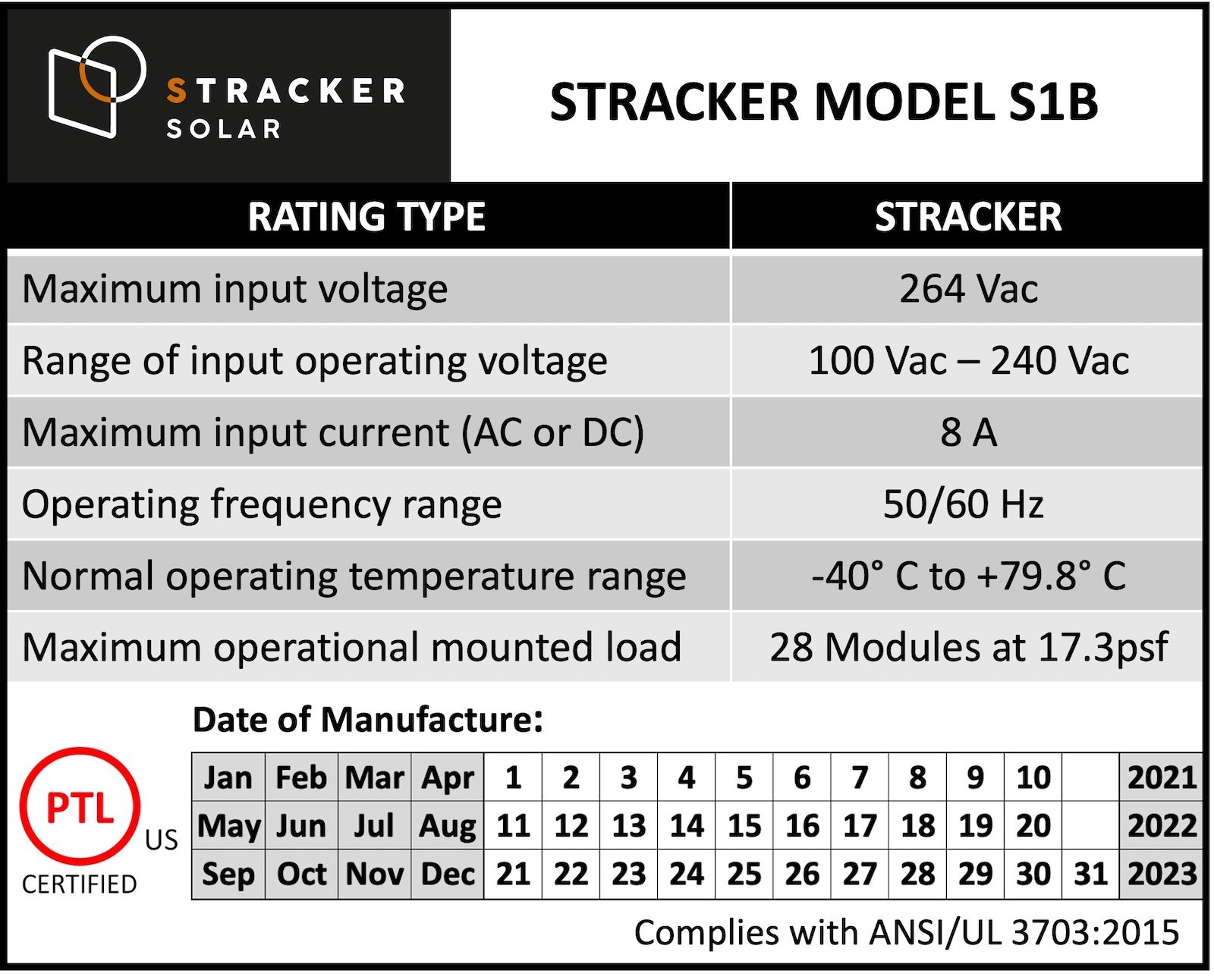

Check your system's certification

The most common and reliable certification for solar panel systems is provided by Underwriters Laboratories, an independent product safety consulting, testing, and certification company. Its UL Mark is a widely respected sign of quality around the world. UL listing assures that a product met the most stringent safety requirements. It indicates that a manufacturer has complied with the highest electrical and mechanical engineering standards. Most manufacturers strive to obtain a UL certificate because, although not required by law, it is difficult to sell a solar panel system in the United States without the UL Mark. Solar PV systems that earn the UL Mark have several advantages: they can be connected to the grid, qualify for government rebates and tax credits, and be covered by insurance.

Tip: Stracker is the only UL-listed elevated dual-axis solar tracking system in the country.